Equipment | Certified Riding Gear – Safety First

Touratech Riding Gear fulfils the highest security standards. In order to give customer full transparency on this sensitive topic, Touratech subjects all its products to the strictest certifications based on the current safety standards.

When it comes to describing textiles or protective materials, marketing strategists develop a highly imaginative prose. Those word creations often include words like »Protect«, »Arma« or something similar, often reinforced by additions like »Pro«, »Super«, »Ultra« or varied through the use of »Soft«. Those creations can be found on countless labels that the customer has to remove before the first use of his newly acquired motorcycle protective riding gear. But what do these often technical-martial sounding descriptions actually say about the product? Strictly speaking: Nothing in terms of the actual protective effect of the riding gear.

What really matters for an informed buying decision is the knowledge about the safety standards that the respective helmet, suit, glove or boot fulfils. As in the nature of standards and norms, there is nothing open to interpretation here. Either a product fulfils all requirements or it does not. That is precisely the reason why Touratech does not use any empty promises, but has its products certified by independent test centres according to the respective current standards.

STANDARDS AND CERTIFICATIONS

Basically, a standard specifies precisely defined requirements for a product. In many areas, standards simply provide clarity about product characteristics. In other areas - motorbike helmets, for example – manufacturer compliance with certain standards is prescribed by law in order to be allowed to sell a product. Standards are set by institutions created specifically for this purpose. In Germany, the German Institute for Standardisation (Deutsches Institut für Normung, DIN) is responsible, while the standardisation organisations CEN/CENELEC set standards valid throughout Europe, and at international level, standards are set by the ISO/IEC organisations.

Standards are always developed according to pre-set basic principles, process- and design rules. And – how could it be otherwise? – there is also a standard for the correct creation of a standard, in Germany the DIN 820. In contrast to some other European countries, motorcyclists in Germany do not have to wear standardised motorbike protective clothing - with the exception of helmets. The ECE standard 22.05, which prescribes minimum standards for head protection, has been in place since the 1980s. This was replaced by the new ECE 22.06 on 1 June 2022.

THE NEW HELMET STANDARD ECE 22.06

With the introduction of ECE 22.06, the test procedure for motorbike helmets has been significantly tightened. The impact test is now much more demanding. Whereas to date measurements were taken at five defined points, in future the testers will be able to determine these points individually. The impact tests are carried out at three speeds. The rotation test, which simulates the rotation of the head during an impact, is completely new. In addition, the visor is subjected to a bullet test in which it has to withstand the impact of a steel ball travelling at 60 metres per second (216 km/h!). In addition, the new helmet standard ECE 22.06 stipulates tests on the chin strap, the helmet fastener and scraper tests. The temperature interval for the extreme tests is also new. These tests, which provide information about the material strength at different temperatures, must be carried out from minus 10 to plus 50 degrees Celsius in accordance with ECE 22.06.

It goes without saying that the new Touratech Aventuro PRO Carbon is certified to this standard. Its helmet shell, laminated from state-of-the-art X-PRO Carbon, far exceeds the requirements. In addition, the Aventuro PRO Carbon has been tested in accordance with the strict US DOT standard, which it also fulfils. Motorbike riders can therefore be sure that they have the maximum possible protection.

Maximum safety: The Touratech Aventuro PRO Carbon is certified in accordance with the current European standard ECE 22.06 and also fulfils the requirements of the strict US DOT standard.

STANDARD VERSUS CERTIFICATION

While a standard basically defines the requirements for a product group, certification confirms that a specific product actually fulfils these requirements. The best-known certification is the "CE labelling", which must refer to the underlying standard. Buyers of motorbike protective equipment should therefore make sure that their product is clearly labelled to indicate the certification. This applies to protectors as well as boots and gloves.

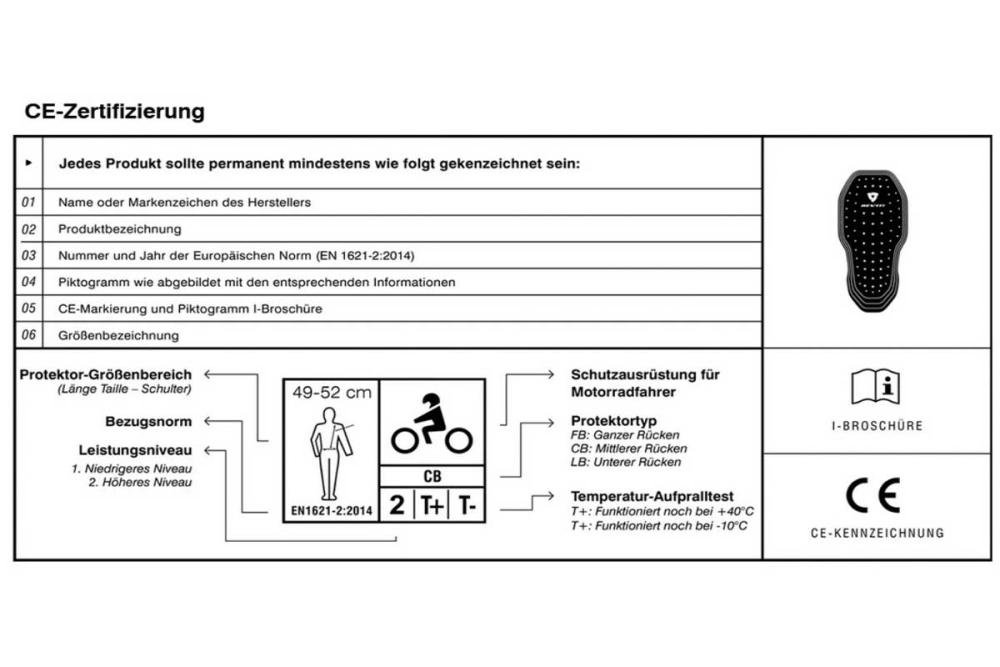

The CE marking must be permanently affixed to the product and contain the following information: Manufacturer's name or trademark, product name, number and year of the European standard (in this case EN 1621-2:2014), pictogram with the relevant information, CE marking, level of protection (in this case level 2).

EN 17092:2020 – THE STANDARD FOR MOTORCYCLE RIDING GEAR

As already mentioned, motorcyclists in Germany are not obliged to wear standardised rider equipment. Nevertheless, the standards are mandatory for manufacturers. This means that anyone bringing motorbike clothing onto the market must ensure that the products offer a minimum level of protection. Since 2019, the EN 17092-2 to EN 17092-6 standards have defined five protection standards. The letter C refers to pure impact protection, while B is used for pure abrasion protection. A is reserved for driver equipment that combines both functions. The protective effect improves from A to AAA.

For a garment to be certified as motorbike protective clothing in accordance with EN 17092:2020, it must undergo a test procedure specified in the standard. This also determines abrasion resistance, tear resistance and seam strength. The better the figure, the higher the protection class. In the test, not only the materials themselves are examined, but also how they are processed together.

PROTECTIVE CLASSES OF PROTECTORS

In order to provide impact protection as well as abrasion protection, motorbike clothing needs to be extensively equipped with protectors. Particularly vulnerable areas are the chest, back, shoulders, elbows, hips and knees. A separate standard defines the protection requirements for the protectors for each body region. The damping of the protectors is tested in precisely defined test set-ups. Depending on the remaining residual force, the protectors correspond to a protection level. At level 1, the average residual force must not exceed 35 kN, and a single impact must not exceed 50 kN. The average residual force of the higher level 2 protectors must be less than 20 kN and no single impact may exceed 30 kN.

A premium suit like the Touratech Compañero Ultimate is of course exclusively equipped with protectors of the highest safety grade Level 2.

CERTIFICATION FROM HEAD TO TOE

Naturally, Touratech boots are also certified in accordance with the current standard.

If you want to enjoy maximum protection on your motorbike, you should ensure that all elements of your riding equipment are certified to the latest standard. This is mandatory for helmets, but also applies to jackets, trousers, gloves and boots. Manufacturers are obliged to permanently affix appropriate labelling to their products.

Safety standards for Motorcycle clothing

| Safety standard | C | B | A | AA | AAA |

| Norm | EN 17092-6 | EN 17092-5 | EN 17092-4 | EN 17092-3 | EN 17092-2 |

| Description | Impact protection only | Abrasion protection only | Aufprallschutz + Abriebschutz |

Impact + Abrasion protection |

Impact + Abrasion protection |

| Example | Chest plate | Bikerjeans without protectors | Simple textile suit | High quality textile suit |

Leather combination suit, Compañero Ultimate |

ABRASION RESISTANCE TEST ACCORDING TO STANDARD EN17092

Rider equipment is categorised into three different risk zones to determine the resistance class. This refers to the risk of the corresponding area coming into contact with the road surface in the event of a fall. Zone 1 is the most at risk, while zone 3 has the lowest probability of contact with asphalt.

Motorbike riders’ protective equipment risk zones

- Zone 1: Shoulders, elbow, hips, knees

- Zone 2: Arms, back, bottom, legs (outside)

- Zone 3: Chest, stomach, arms (inside), legs (inside, back)

The risk zones are subjected to an abrasion test. For this purpose, the “Darmstadt method” is used, which simulates the sliding of the material to be tested on asphalt in a standardised device. To achieve protection standard AAA, a fall at a speed of 120 km/h is simulated for zone 1. For protection standard AA, the test is carried out at 70 km/h, for class A only at 45 km/h. To pass the test for the respective protection standard, the penetration of the material at the tested point must be less than five millimetres. The tear resistance of the material and the strength of the seams are also tested.

SAFETY STANDARD AAA: THE COMPAÑERO ULTIMATE

The Touratech Compañero Ultimate is one of the very few textile suits in the world to have the highest possible AAA certification as motorbike protective equipment in accordance with the EN 17092-2:2020 standard. This standard of protection is otherwise only offered by leather suits. To achieve this exceptionally high level, the development team at Touratech and Stadler combined state-of-the-art technologies. A high-strength yet supple three-layer laminate and protectors of protection class level 2 were used. The problem in achieving the high abrasion and tear resistance is not so much the likely fall points, where you can work with very solid material. More difficult are the large areas, which must not be too stiff to ensure a high level of comfort. This is why the Compañero Ultimate has a multi-layer construction. This allows the different layers/materials to move against each other, so the jacket and trousers remain as flexible as a normal three-layer laminate, and breathability is not restricted. The patented SASS ventilation system covers the direct openings, so there are no weak points in the outer layer. The Touratech Compañero Ultimate also has the best possible protector equipment. Protectors of the highest protection class Level 2 are used in all areas at risk of falling, i.e. chest, back, shoulders, elbows, hips and knees. The many ventilation openings also increase riding comfort and therefore also physical and mental fitness - an important factor for active safety. But there is no standard for that yet.